【簡介】

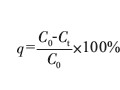

摘要:采用先硬質氧化再染黑色的方法對光學系統(tǒng)用鋁合金材料進行了處理。檢測了氧化膜層的厚度、顯微硬度和反射率,分析了溶液成分、電流密度、溫度和氧化時間對氧化膜反射率的影響。結果表明,采用含260~3009幾硫酸、l0~15 9/L草酸和l0~20 9/L多元醇的溶液在溫度5~7 ℃、電流密度2~3 A/dm2的條件下氧化50 min,可獲得厚度l5 um、顯微硬度450 HV、反射率低于8.4%的硬質氧化膜層,該氧化膜適用于高精度軍用光學變焦系統(tǒng)。

關鍵詞:光學變焦系統(tǒng);鋁合金;硬質氧化;顯微硬度;反射率

中圖分類號;TGl74.41;TQl53.6 文獻標志碼:A

文章編號:1004—227X(2009)03—0024—03

Hard anodizing process on aluminum alloy materials for optical system//JIANG Wei*,SHEN De-xin,WANG Li-bo

Abstract:A method of hard anodizing followed by black dyeing was used to treat aluminum alloys for optical system. The thickness,microhardness and reflectance of oxide film were measured.and the effects of solution composition. current density,temperature and oxidation time on reflectance of oxide film were analyzed.The results showed tllat a hard oxide film with thickness of l 5 μm.micro— hardness of 450 HV and reflectance below 8.4%can be obtained in a solution containing 260.

Keywords:optical zoom system;aluminum alloy;hard anodizing;microhardness;reflectance

First-author’s address:Changchun UP Optotech C0., Ltd.,Changchun l30031,China

1 前言

隨著國防工業(yè)的不斷發(fā)展,光電儀器的應用日益廣泛。為了監(jiān)視、測量和跟蹤目標的彈道和軌道,常需采用可連續(xù)變焦的光學系統(tǒng)。而變焦機構是連續(xù)變焦系統(tǒng)的核心部件,對系統(tǒng)的跟蹤精度[1]、成像質量等有顯著影響。變焦機構由凸輪、滑架和導軌架組成,為保證光學系統(tǒng)的可靠運行、減少光路雜散光,上述零件應具有一定的硬度和較低的鏡面反射率。本文對變焦機構零件所用的