【簡介】

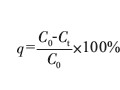

摘要:在45#鋼上化學(xué)鍍Ni-P-PTFE復(fù)合鍍層,其工藝流程主要包括化學(xué)機械拋光、堿性除油、活化、化學(xué)鍍和干燥。研究了主鹽和還原劑質(zhì)量濃度、pH、溫度以及PTFE體積分數(shù)對鍍速的影響。觀察了Ni-P-PTFE鍍層的表面形貌,測試了鍍層的摩擦學(xué)性能。結(jié)果表明:當(dāng)工藝條件為25 g/L硫酸鎳、30 g/L次磷酸鈉、10 mL/L PTFE、pH 4.6和溫度(92士2)℃時,鍍速最佳,鍍層的摩擦因數(shù)在0.16~0.20之間,具有優(yōu)良的耐磨性能。

關(guān)鍵詞:鎳—磷合金;聚四氟乙烯;化學(xué)復(fù)合鍍;鍍速;摩擦因數(shù):耐磨性

中圖分類號:TQl53 文章標(biāo)志碼:A

文章編號:1004—227X(2009)03—0017—04

Study on deposition rate and tribological properties of electrolessly plated Ni-P-PTFE composite coating// WANG Liu-bin,ZHAO Yong-WU*

Abstract:A Ni-P-PTFE composite coating was prepared on 45 steel.The process flow includes chemo—mechanical polishin9,alkaline degreasing,activating,electroless plating, and drying.The effects of the mass concentrations of main salt and reducing agent,pH,temperature and PTFE volume fraction on deposition rate were studied.The surface morphology of the Ni-P-PTFE composite coating was observed and its tribological properties were tested.The results showed that the optimal deposition rate was obtained with

Keywords:nickel-phosphorus alloy;polytetrafluoroethylene; electroless composite platin9;deposition rate;friction factor; wear resistance

First-author’S address:School of Mechanical Engineerin9, Jiangnan University,WuXi 214122,China

1 前言

Ni-P鍍層為非晶態(tài)合金鍍層,具有高硬度、高導(dǎo)電性以及良好的耐蝕性、耐磨性、可焊性、磁性屏蔽等性能,廣泛應(yīng)用于汽車,、航空、電子、機械、化工和石油工業(yè)等領(lǐng)域[l]。PTFE(聚四氟乙烯)粒子是一種干態(tài)潤滑劑,其表面能非常低,不易黏結(jié),具有良好的自潤滑、憎水、憎油性能以及極低的摩擦因數(shù),但硬度低,耐磨能力差[2-4]。將PTFE加入Ni-P化學(xué)鍍液中,可獲得Ni-P-PTFE復(fù)合鍍層。本研究所獲得的 Ni-P-PTFE復(fù)合鍍層性能優(yōu)良,鍍液穩(wěn)定性好(可達8個周期以上),具有良好的應(yīng)用前景。