【簡介】

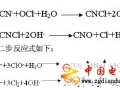

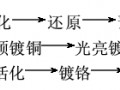

摘要:利用4,4,.二苯基甲烷二異氰酸酯(MDI)與雙羥基聚甲基苯基硅氧烷分子中的羥基反應制得叫Nc0封端的預聚體,再將該預聚體與環(huán)氧丙烯酸酯(EA)混合,得到有機硅化學改性環(huán)氧丙烯酸酯。在此基礎上,以氨基樹脂為固化劑,制得常溫固化涂層;以2一羥基一2一甲基一l一苯基一l一丙酮(即1103)為光引發(fā)劑,在紫外光照射下制得常溫光固化涂層;以氨基樹脂為固化劑,l l03為光引發(fā)劑,在紫外光照射下制得常溫混雜聚合涂層。討論了上述3種涂層的硬度隨固化時間的變化,用熱重一差熱分析(TG.DTA)技術研究了三者的耐溫性。結果表明:常溫混雜聚合涂層的硬度隨時間的延長增加得最快,光固化涂層次之,常溫固化涂層最慢。3種涂層都能耐420 ℃左右的溫度。

關鍵詞:環(huán)氧丙烯酸酯;有機硅樹脂;改性;混雜聚合;紫外光固化;硬度:耐熱性

中圖分類號:TQ630.79 文獻標志碼:A

文章編號:1004—227X(2009)02—0050—03

Study on hybrid polymerized silicone modified epoxy acrylate//LI Zhao.Lei,GAO Yan.Min*,ZHANG Li.Hua Abstract:A chemically silicone.modified epoxy acrylate was obtained by mixing epoxy acrylate(EA)and a—NC0-end prepolymer which was prepared by the reaction of 4,4’-liphenylmethane diisocyanate(MDI)and hydroxyl groups existing in dihydroxy poly(methylphenylsiloxane) molecule.Based on the modified epoxy acrylate,three types of coating were separately prepared:room—temperature curable coating with amino resin as curing agent,room- temperature UV curable coating with 2一hydroxv一2一methyl-1-phenyl-l-propanone(code:1103)as photoinitiator under UV radiation.and room temperature hybrid polymerized coating with amino resin as curing agent and 1103 as photo— initiator under UV radiation.The hardness variations of the three coatings with curing time were discussed and their thermal resistance was studied by thermogravimetric. differential thermal analysis fTG.DTAl technique.The results showed that the hardness of the room.Temperature hybrid polymerized coating increases rapidly with curing time,followed by the room—temperature UV cured coatin9, and the increase of hardness for room-temperature cured coating with time is the slowest.All of the three coatings can be resistant to the temperature of about 420℃.

Keywords:epoxy acrylate;silicone resin;modification; hybrid polymerization;ultraviolet curin9;hardness;thermal resistance

First-author’S address:Jiangsu University ofScience and Technology,Jiangsu Provincial key Laboratory of Advanced Welding Technology,Zhenjian9 212003,China

1 前言

<